Installation of boilers in a private house. Requirements for the room for installing a gas boiler in the house. Flue gas removal

Gas boilers are widely used for operation as part of autonomous heating systems. Ease of operation, low cost of "blue" fuel - all this contributes to their popularity among homeowners, especially in the private sector. At the same time, working with these units requires special care. Accordingly, the premises in which they are located must also meet certain standards and meet the necessary requirements.

Few of the owners of residential buildings thought about the question of what is the correct name of the “room” in which the gas boiler will be installed (). And the order of its arrangement and the conditions that will need to be fulfilled depend on the name.

You can often hear - "home boiler room". Is it correct? Before deciding on the requirements that apply to this room, you should understand the terminology. After all, it is much easier to equip a full-fledged furnace than a boiler room. For example, fewer problems with the installation of electrical equipment.

Without going into details, the subtleties of definitions and various additions to the main regulatory documents, we point out that a furnace is either a separate room attached to the building, or a room specially allocated for installing the boiler in the house itself. This is the first. In addition, no more than 2 units of gas heating appliances (boilers) can be installed in it. At the same time, there is a limitation on their total power - no more than 200 kW. Therefore, with regard to a private house (with rare exceptions), it is the furnace, and not the boiler room, that is equipped.

It should be noted that we are talking about floor-mounted boilers. Wall models can be mounted in almost any room, except for those in which there is constant excess or high humidity (laundry, bathroom or toilet room; swimming pools). Also, they can not be installed in bedrooms and nurseries. As a rule, for the convenience of controlling a wall-mounted boiler, it is located in the kitchen (up to 30 kW). But for floor-standing appliances, you need a full-fledged furnace.

Once again, we note that we are talking about gas floor boilers.

Requirements for the arrangement of the "furnace"

Room dimensions

All gas boilers have design differences, including the type of combustion chamber. If it is closed (a coaxial chimney is laid), then the dimensions of the room do not play a role. But for models with open cameras there are certain standards (at a minimum):

- 7.5 m3 - for devices with a power of up to 30 kW;

- 13.5 m3 - up to 60 kW;

- 15 m3 - for boilers with a capacity of more than 60 kW. At the same time, for each additional “kilowatt” of the device, it is necessary to add 0.2 m3 of the room.

Volume, as you know, is the product of quantities: length x width x height. So, the last parameter is strictly fixed and cannot be less than 2 m. Therefore, you need to choose the size of the room with an “eye” on its height.

Furnace location

On any floor, including basement and basement. This applies to all models where the movement of fluid through pipes (water, antifreeze) is forced (by a pump). But if the boiler is of the TLO series (natural circulation of the coolant), then only in the basement or basement.

The door to the furnace must comply with fire safety standards (type III). Below - the gap between its bottom and the floor - not less than 0.025 m2. If the door adjoins the floor tightly, then a small window is set up in its lower part, closed with a grate.

illumination

For each "cube" of the room - at least 0.03 m2 of glazed surface. Moreover, at least one window (at least 0.25 m2) - to the street (this does not apply to devices with closed cameras)

Ventilation

Firstly, the presence of a window is mandatory. Secondly, it must be forced. For 1 hour, it should provide 3-fold air exchange.

Boiler location

- From the front panel of the boiler to the wall (door) - at least 1 m.

- The device must be freely accessible from all sides. This is necessary for the convenience of carrying out maintenance work in full.

- The boilers are placed on a pedestal, the height of which, as well as fire requirements for its arrangement, are specified in the Installation Instructions for the device.

- The wall (or walls) near which the boiler is located must be made of non-combustible materials (or reliably protected from thermal effects).

It should be noted that all of the above applies to private houses with centralized gas supply. If liquefied gas (cylinders) is used, then there are some features. For example, in this case, the boiler cannot be installed in the basement. Therefore, such nuances should be clarified further.

In addition, there are features depending on what material the house is built from, interfloor ceilings are made. Therefore, before connecting the gas supply, so that there are no problems, it is advisable to invite a specialist to inspect the furnace and identify shortcomings.

You need to understand that the requirements are constantly being finalized, changed, refined. In addition, each region has its own regulatory framework. Therefore, a professional tip will not be superfluous, but we have indicated the main and most important points.

A gas heating boiler for private households is considered one of the best options because it has a high efficiency and makes it easy to adjust the intensity of heating. The cost of purchasing and installing this heating unit will pay off quickly enough, since gas as a fuel is economically viable.

When it is planned to install a gas boiler in a private house, the requirements for it and the room where it will be located should be clarified in advance. As practice shows, the owner of the property will have to prepare a solid folder of various documents and obtain permits from certain authorities. This is not a pleasant occupation, but it is necessary.

Documents regulating the installation of a gas boiler

First of all, before proceeding with the installation of gas equipment in a private house, it is advisable for its owner to familiarize himself with the regulatory documentation containing all the rules and requirements that will need to be followed when creating autonomous heating.

All the required information can be found in SNiP 31-02-2001. In addition to these Building Regulations and Rules, you need to familiarize yourself with other documents, including: SNiP 41-01-2003; 21-01-97; 2.04.01-85. The rules for installing a boiler house in a private household are regulated by SNiP 2.04.08-87.

Installation approval, regulatory requirements

In order for the installation and connection of a gas boiler in a private house to be carried out, it is not enough to read SNiPs. First of all, you need to obtain technical conditions, which in the future will be the basis for performing work related to connecting the device to centralized gas networks.

The property owner must submit an application to the service responsible for the gas supply at the place of residence. It should indicate the planned gas consumption for heating the house and for other domestic or household needs. This parameter has an approximate value, based on the standards prescribed in SNiP 31-02.

So, the volumes of gas per day for a single-family home are:

- for cooking on a gas stove -0.5 m³;

- for supplying hot water by means of a flow-type gas heater -0.5 m³;

- for heat supply by a gas unit with a laid water circuit - from 7 to 12 m³ for Russian regions of the middle lane.

In the local service that controls the gas supply and installation of boiler equipment, the submitted application is considered by specialists. As a result, the owner of the building receives a document in which the technical conditions are prescribed or a reasoned refusal is given.

The procedure for considering an application for installing a gas boiler in a private house usually takes from 7 to 30 days, which depends on the speed of decision-making in this controlling organization. If the request is satisfied after receiving the technical conditions, they must be fully implemented during the installation of the equipment.

A document with a positive decision is also considered a permit for the installation of a gas boiler, and therefore for the start of the relevant work. Every homeowner should be aware that it is illegal to install this type of device without specifications. In addition, an independent unauthorized installation of the boiler is not safe.

Designing a gas boiler installation in a private house

When the technical conditions are received by the owner of the object, he can begin to draw up project documentation. It is developed on the basis of the requirements set forth in the technical conditions.

The project for the installation of a gas boiler must contain a diagram describing the laying of gas communications, and for private households - in the area before entering the residential building, indicating this place on the drawing.

The project should be developed exclusively by design engineers who have received a license to carry out this type of work. Usually, in an organization that controls gas supply in a settlement or region, there is a design department, whose employees perform the necessary surveys, relevant calculations and draw them up in the form of projects with drawings and diagrams.

Approval of project documentation

Then the developed project is sent for approval to the territorial office of the organization that controls the gas supply of the household, where the equipment will be installed.

The time period required for this depends on how complex the scheme for installing a gas boiler in a private house and laying gas communications is. It can range from 7 days to 3 months.

Documents are attached to the project that requires approval, which describe the characteristics of the equipment for the boiler room:

- Technical passport of the gas appliance.

- Manufacturer's instructions for its use.

- Certificates confirming the compliance of the equipment with sanitary and hygienic and technical parameters.

- Expert opinion that this unit meets all safety requirements.

All of the above documents are issued to the one who purchases the device, and they are issued by the manufacturer of heating equipment.

There are situations when a project does not receive an approval resolution. Then, in addition to a reasoned refusal, the applicant should be given a list of necessary actions, as a result of which it will be possible to obtain a positive verdict. When the project is approved, it is formalized accordingly. Now you can proceed to practical activities related to the installation of a gas boiler in a private house.

boiler room requirements

To use gas equipment with a power of 30 kW or more, you will need a separate room that complies with all applicable rules and regulations.

Most often, one of the rooms in the basement or basement is equipped as a boiler room. True, such an installation of a heating unit is allowed only for single-family residential buildings.

In private households, the rules for installing a gas boiler allow the use of equipment of any power, since most often it is placed in a separate room attached to the house, which allows you to provide heat not only for living rooms, but also for utility rooms.

Important requirements that the boiler room must meet are as follows:

- The area of the minimum room for a gas boiler based on one unit is 4 m². At the same time, more than two devices cannot be placed in one room. This size of the boiler room in a private house is required.

- Ceiling height should be at least 2.0-2.5 meters.

- To provide natural light, it is necessary to have a window, the size of which is determined at the rate of 0.3 m² per 10 m³ of the volume of the room for a gas boiler, but not less than 0.5 m². A certain distance from the gas boiler to the window is also provided, in terms of safety.

- The width of the doorway cannot be less than 80 centimeters.

- The minimum distance from the front door to the unit is -100 centimeters, but it is better if it is 130–150 centimeters.

- In order to create conditions for the implementation of repair or preventive measures, a free space of at least 130 centimeters should be provided in front of the boiler.

- Proper installation of a gas boiler in a private house means that it is located in a horizontal position and is stable. This minimizes the possible noise level due to vibration.

- The floor and walls must be made of non-combustible materials, in addition, the floor covering must be absolutely even.

- Cold water must be brought into the boiler room, and a sewer drain for the coolant must be equipped in the floor.

- For electrical outlets, a ground loop is required, since the ignition or pump is connected to the power supply.

- Easy access to the chimney, or rather to the inspection window, should be provided in order to control the patency of the channels and clean them.

Ventilation and smoke removal

The rules for installing a gas boiler in an apartment and a private house provide for the arrangement of ventilation systems and the removal of gas combustion products in the boiler room. Their malfunction or ineffective functioning may result in equipment failure or lead to an emergency.

The regulatory documentation for ventilation and chimney in a private household lists a number of requirements:

- Smoke exhaust and ventilation channels cannot be combined, they are made separate.

- In order for fresh air to enter the boiler room, forced ventilation should be installed in it. The entrance window is arranged at the bottom of the door or outer wall. The size of the ventilation window opening should be at least 1/30 of the area of the room, but not less than 80 mm² per 1 kW of boiler power in the case when the air flow comes from the street, and at least 300 mm² per 1 kW if from other sources.

- Ventilation ducts should always be kept open, as air flows must constantly circulate.

- The boiler is recommended to be located in close proximity to the chimney.

- The chimney installed in the wall should have two inlet channels, while the main one is intended for installing a chimney, and the other is revision, for technological cleaning, it is located below the first one by at least 25 centimeters.

- The cross section of the chimney exhaust opening cannot be less than the same parameter for the outlet pipe of the gas unit.

- The chimney structure should not have more than three bends and turns.

- For the manufacture of chimneys, stainless or carbon steel is used. Installation of asbestos-concrete or other pipes made from laminated materials is allowed at a distance of at least 50 centimeters from the flue pipe of the heating unit.

- In order to ensure the safe operation of the device and the efficient operation of the heating system, it is necessary to create conditions to maintain the required traction force. Therefore, it is necessary to calculate both the entire height of the chimney pipe and the height of its location above the roof surface so that the head is not in the zone of wind backwater.

The rules and conditions for the installation of a gas boiler set the standards for its chimney design:

- the pipe should rise above a flat roof without a ridge no less than 50 centimeters above the roof or parapet, if it is equipped along its perimeter;

- when the chimney passes through the roof slope at a distance of at least 150 centimeters from the ridge, then the pipe head must be raised by at least 50 centimeters;

- if the chimney outlet through the pitched roof is laid at a distance of 150–300 centimeters from the ridge horizontally, it is necessary to raise the head to a level not lower than the top point of the ridge;

- in the case when the pipe passes through the pitched roof at a distance of more than 300 centimeters from the ridge, then its outlet is located on a conditional line drawn at an angle of 10 degrees from the top of the ridge to the horizon.

Information about gas boilers

In the domestic market, consumers are offered an extensive range of gas equipment. To make the right choice, you need to study the information on heating units from different manufacturers.

Gas boilers are divided into several types depending on:

- constructive device;

- installation method;

- rated power;

- ignition principle;

- technologies for the removal of combustion products.

According to the basic design, the units are single- and double-circuit:

- Boilers of the first type are needed to provide a heating system, and if you plan to use them for hot water supply, you will need a device called an indirect heating boiler. This unit is designated as a heating gas water heating unit, abbreviated as AOGV.

- Double-circuit models are able to provide both heating of the household and supply residents with hot water. They can function as a flow-through heating option, or be equipped with a built-in boiler. It not only heats the water, but also maintains some of its supply. On double-circuit devices, the letter designation AKGV is applied - a combined gas water heating unit.

Depending on the method of installing a floor-standing gas boiler in a private house, it can be either wall-mounted or floor-mounted:

- Wall models are becoming increasingly popular, as they are used even in apartment conditions. They are convenient in that the construction of a structure that removes smoke is not required to remove combustion products. Smoke extraction can be carried out directly to the atmosphere through an external wall by installing a coaxial chimney, which also provides the air supply necessary for burning fuel.

- Floor-mounted units differ from wall-mounted models in greater power. Installation of a floor-standing gas boiler in a private house is usually performed in boiler rooms so that they do not clutter up domestic premises.

Today, all manufactured heating units are equipped with automatic protective systems of various levels of complexity, but in any case, they provide for the shutdown of the fuel supply to the burners in the presence of leaks or interruptions in the operation of the gas main, excessive heating of the coolant or insufficient draft force in the chimney.

Before purchasing a boiler, you should pay attention to its power in kWh, which means the production of a certain amount of thermal energy per unit of time. The optimal model is selected taking into account this parameter based on the calculations performed, depending on the heated area and the size of the gas boiler for a private house.

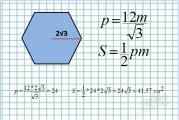

For calculations, use the formula W \u003d S × Wsp / 10, where:

W is the power of the device;

S - heated area;

Wsp - specific power for heat supply of 10 m².

Depending on the region of location, the specific power may vary. For example, if for the northern regions it is 1.5 - 2.0 kW, then for the southern regions it is different - 0.7 - 0.9 kW.

But such an approach to determining power cannot be called accurate, since it does not take into account the characteristics of a particular household. Before installing a gas boiler in a private house, you can turn to specialists with extensive experience in carrying out such calculations, who will calculate this parameter for each room. Knowing the exact amount of power, it is not difficult to make the optimal choice of gas equipment.

Rules for installation and connection of a gas boiler

Before connecting a gas boiler in a private house, its owner must contact the gas service specialists who have undergone special training and have been certified, and also have a license to carry out such work.

Professional installation is a costly undertaking, but its high-quality implementation and safe living in a private house will be guaranteed.

There are times when property owners are allowed to independently install a gas unit, but for this you must obtain personal permission from the controlling organization. But even in such a situation, specialists should still accept the installed equipment, as well as perform a trial run.

The beginning of the installation of the heater consists of several stages:

- First of all, you should make sure that the necessary operating conditions for a gas boiler in a private house are created and that all components are prepared for its installation. To do this, you need to read the technical condition for the device again and study the previously approved project.

- Then the floor boiler is placed on a prepared, reliable, solid and even base made of non-combustible materials. The best surface on which to install a gas appliance is a concrete screed. Ceramic tiles or a sheet of metal are laid on it. The base must have such an area that it covers the space in front of the firebox in front of the boiler by about 40-50 centimeters.

- If the design provides for the presence of legs, it should be ensured that the unit rests completely on them. An unstable location in this case is unacceptable.

- Wall models are hung on the walls at a height of 100-160 centimeters from the floor using brackets or mounting brackets supplied with the equipment. Their locations are marked using the building level.

It must be remembered that the installation of a gas boiler in a boiler room or other room is carried out in such a way that it is at a distance from electrical appliances, and access to it is from all sides.

There are certain rules for the location of a gas boiler in a private house - they provide for compliance with a certain distance to the ceiling and walls:

- From the surface of the unit to the uninsulated ceiling, the gap must be at least 120 centimeters.

- From the side wall of the floor model to the wall without protective insulation cannot be less than 32 centimeters. When a sheet of asbestos is attached to the wall, covered with a metal sheet, then the gap can be reduced to 26 centimeters.

- There must be at least 50 centimeters between the unprotected wall and the chimney. If the wall is covered with asbestos and a sheet of metal, the gap can be reduced to 25 centimeters.

- Both hinged and floor models of boilers must be connected to the chimney system. To do this, they have an outlet pipe, its connection to the chimney is made absolutely tight, since even through small gaps combustion products can leak. This work is carried out, adhering to the “smoke” docking technology. To do this, the unit's branch pipe must be inserted into the socket of the flue pipe.

- When connecting the boiler to the water supply system, a sump is installed before entering the device - this is the name of the coarse water filter. On both sides of it, stopcocks are mounted, necessary to shut off the water flow in case of replacing or cleaning the filter. It is advisable to install a filter with a similar piping on the return pipe of the water circuit in front of the boiler. As a result, due to the cleaning of the coolant, the heat exchanger will not clog.

- Usually, a circulation pump is also mounted on the return pipeline, which should be tied with a bypass and stopcocks, so that, if necessary, it is possible to switch the circulation mode from forced to natural.

- It is advisable to choose the connection point to the water supply before the first branching of the pipes of the circuit and as close as possible to the entrance of the pipeline into the wall. This measure helps to ensure the required pressure level in the process of filling the heating system.

- In floor-standing models, the pipe for connecting the pipes for supplying the water circuit is made in the upper part of the boiler, and the “return” pipe is located at the bottom. In wall-mounted units, both nozzles are located at the bottom.

- The gas supply pipe to which the supply to the unit is connected must be equipped with a valve to shut off the gas supply.

When the installation of the heating boiler and its connection to the heat supply circuit is completed, the equipment is tested for tightness. This process, called "crimping", is carried out by specialists who use devices that create excess pressure in the system. During testing, there should be no leakage of coolant at the joints.

Authorized employees of the gas service are required to check the tightness of the connection of flexible hoses and all components of the gas block of the device. After that, they conduct a test run of the unit and check the correct functioning of its operation in different operating modes.

After the completion of the control and testing activities, if the conditions for installing a gas boiler in a private house are met and the device works flawlessly, the controllers draw up an act - a permit document that allows it to be operated.

Basic rules for using a gas unit

It is necessary to use heating gas appliances in compliance with certain rules:

- The boiler room or other room should always be dry.

- Filters for the heat carrier should be cleaned of dirt in a timely manner in order to extend the life of the heat exchanger.

- It is strictly forbidden to make independent changes to the structural device of the boiler.

- Cleaning of the flue structure pipe from combustion products deposited on its walls should be carried out in a timely manner.

- In a private household or boiler room, it is advisable to install a gas analyzer that helps to identify malfunctions in the functioning of gas equipment.

- Timely maintenance of the heating unit should not be avoided, which experts recommend to carry out before the start of the heating season and after its completion. To do this, you need to invite a master who will comprehensively check the condition and operation of the chimney, ventilation system, filters, burner and boiler as a whole.

A qualified installation and compliance with preventive measures can ensure the long and trouble-free operation of gas equipment, and, accordingly, the entire heating system of a household.

Installing a gas boiler in a private house requires solving some problems. To the premises and equipment there are specific requirements which will have to be strictly followed, because not only the quality of operation, but also safety depends on this.

Preparation for the installation of a gas boiler in a private house includes important steps for its design and coordination of installation with the relevant organizations. At this stage, the selection or construction room for placing the boiler, and also selected required type of equipment.

It is important to correctly estimate the required gas consumption. This fuel is quite available in many regions of the country, but its additional selection from a centralized network should require permits.

An important preparatory step is the choice of the type of equipment. Gas boilers have 2 main varieties:

- Single circuit type. It is intended only for heating and has a simpler design.

- can simultaneously heat the house and provide hot water.

Boilers also differ in the way they are installed. There are wall and floor options. Each of them has its pros and cons, which is taken into account when choosing equipment.

The choice of device for power depends on the size of the house (see:). In this case, the climatic coefficient (Kk) is taken into account. It is for the central regions (including Moscow) - 1.2-1.4; southern regions - 0.8-0.9; north of the country - 1.4-2. Estimated calculation is carried out according to the formula КкхS/10. For example, for a house in the Moscow region with an area of 120 m², it is advisable to choose a boiler with a capacity of 120x1.2 / 10, i.e. 14-15 kW.

Regulatory Documentation

The main document regulating the installation of gas equipment in a private house is SNiP 42.01-2002 "Gas distribution systems". It contains the most important rules and regulations.

In addition, it would not be superfluous to familiarize yourself with the requirements and recommendations regarding heating and ventilation systems ( SNiP 41.01-2003), the procedure for ensuring gas supply ( SNiP 2 04.08-87). Useful information can be obtained from SNiP 31.01-2003 on the procedure for installing gas equipment in residential buildings.

Installation approval

In order to legally start the installation of a gas boiler, it is necessary to prepare and agree on certain documents. First of all, it should be clarified the possibility of extracting gas in the required volume. For this, an agreement (contract) is concluded on the supply of natural gas to an individual (individual developer).

The most important documents for connecting are Specifications. They are issued in the relevant territorial gas service. To obtain a document, you must apply to such an organization, indicating the purpose of additional gas supply and the planned volume of gas consumption. Registration of technical specifications is carried out within 8-12 days.

Important! The issued document clearly specifies the installation features of the installation; from the moment of issuance, it is considered an official permission to start work.

Project development

The technical specifications fix only the conditions for installing a gas boiler, but to start installing the equipment, you must go through the following stage - development and approval of project documentation.

The technical specifications fix only the conditions for installing a gas boiler, but to start installing the equipment, you must go through the following stage - development and approval of project documentation.

In fact, the Gas Supply project is needed, which clearly defines the scheme for installing the boiler itself and supplying gas to the point of its selection from the central highway.

It is developed by specialized organizations that have the appropriate license. The document must be approved by the state organization, which is entrusted with supervisory powers (usually Raygaz or Oblgaz).

The following documents are attached to the project for approval:

- Technical passport for equipment.

- Instruction manual for gas boiler.

- Sanitary certificate and certificate of technical conformity.

- Expert opinion on the compliance of equipment with technical requirements.

All of these documents must be provided by the equipment manufacturer. Depending on the complexity of the installation, project coordination can take from 6-7 days to 2-3 months. In case of refusal to agree, a motivation should be issued indicating the necessary changes in the project. The final agreed version of the project is certified by a seal.

Installation rules

The heating boiler must be installed in a separate room, which is subject to increased requirements:

The heating boiler must be installed in a separate room, which is subject to increased requirements:

- Gas equipment is mounted in a specially designated room. In a private house, taking into account all the norms, a boiler room can be equipped on any floor and in the basement. It is not allowed to put a gas boiler in the living room, bathroom, bathroom and kitchen.

- The minimum allowable area of the room is set based on the power of the boiler. Permissible minimum - 4 m².

- The ceiling in the room must be raised to a height of more than 2.6 m.

- Mandatory element in the room - opening window. The norm is set - 3 cm² of window area for every 1 m² of the total area of \u200b\u200bthe boiler room.

- The entrance door to the room should be wider than 80 cm. At the top, between the doorway and the door leaf, a gap of more than 24 mm is left for natural ventilation.

- It is not allowed to use combustible facing materials in the decoration of the room. Do not make false ceilings or raised floors.

- The room should have adequate lighting and fresh air.

- It is necessary to exclude the accumulation of moisture in the boiler room. Humidification of the environment makes it difficult to remove gas vapors.

- It is not allowed to operate a gas boiler without plumbing.

It should be borne in mind that the requirements for the boiler room are mandatory. Given that violation of the rules is fraught with danger, improper arrangement is punishable by fines and a ban on the operation of equipment.

Requirements for individual rooms

A boiler room in a separate building is organized with a boiler power of more than 150 kW or at the request of the owner with any equipment. This option increases safety, completely eliminates the penetration of gas into the house, however, it requires the installation of a heating main with reliable thermal insulation.

During the construction of a separate structure, non-combustible building materials are used. Preference is given to block and brickwork. For external cladding, metal multilayer "sandwiches" can be used. The floor covering is made of reinforced concrete slabs. When arranging the roof, the emphasis is on a metal profile and non-combustible roofing materials.

A separate room must fully meet the above requirements. With a boiler power of more than 100 kW, the minimum area of the room is set to 15 m². More powerful installations require adjustment of this indicator - 0.2 m² additionally for every 1 kW.

If the boiler has a mass of more than 210 kg, then a foundation must be erected, which is independent of the foundation of the building itself. It rises above the floor level to a height of 12-15 cm.

Annex equipment

A special extension to a residential building is most often used for boilers with a capacity of 50-100 kW or in the absence of the necessary premises for low-power equipment inside the house. This option is quite popular. In this case, it is important to provide fireproof protection of the wooden wall in the area where the extension comes into contact with it. Fire resistance must be at least 0.7 hours.

The extension room must comply with all established standards. Increased requirements for the front door. It should be metal, open outward and be fixed in such a way that it can easily fly out from the blast wave. Natural ventilation is an important requirement.

For air inflow, it is assumed that there are holes and gaps, and their area is normalized by such a condition - 8 cm² for every 1 kW of boiler power.

Requirements for equipment and its elements

Gas supply to the boiler room is allowed only after the correct installation has been verified by a competent representative of the district or regional gas service. Before putting it into operation, the system must be pressure tested at a pressure of up to 1.9 atm.

Important! There must be no air left in the system, and all components must be checked for leaks.

The following general requirements for the equipment and its parts must be observed:

- ensuring free access to the equipment from all sides;

- gas pipes can be made exclusively of metal;

- a prerequisite is the presence of a gas flow meter;

- the equipment must be reliably grounded in accordance with the standards established for electrical installations;

- to avoid emergencies, it is necessary to install gas analyzer, signaling the presence of a gas leak and automatic valve to shut off the gas supply in case of depressurization.

The operation of a gas boiler is sufficiently dependent on electricity. To eliminate problems, it is advisable to install a voltage stabilizer, as well as uninterruptible power supplies.

Arrangement of ventilation and chimney

The most important element of the arrangement of the boiler room is a reliable ventilation system. It is designed to exclude:

- accumulation of carbon monoxide and accumulation of gas in the presence of small leaks;

- elimination of soot settling on the surface of walls and ceilings;

- providing comfortable conditions for service personnel.

Ventilation is provided by a combination of natural and forced methods.

Natural ventilation involves the presence of opening windows (in accordance with the specified standards), slots in the doorway and special ventilation holes in the wall. They usually have a diameter of 12-16 cm, and their number depends on the area of \u200b\u200bthe room and the power of the equipment.

The inflow of fresh air occurs through the lugs in the lower part of the wall, and the outflow occurs under the ceiling on the opposite side of the wall or through the roof. Openings should be covered with a protective grille.

Forced ventilation increases the safety of equipment operation. When using powerful boilers, natural ventilation will not cope, and therefore exhaust fans are installed. For removal, exhaust, ventilation pipes are mounted.

A chimney (more correctly, a gas outlet) is an indispensable element for a boiler room. The following requirements are imposed on its arrangement:

- the chimney of the boiler room is a separate structure that is not connected with other smoke exhaust systems in the house;

- the horizontal branch section cannot exceed 2.8 m;

- the number of knees (curvature) - no more than 3;

- the outlet diameter cannot be less than the connecting pipe;

- the outer section of the chimney is led above the roof and must rise above the ridge to a height of at least 60-70 cm.

The diameter of the chimney depends on the power of the boiler and must take into account the set ratio. So with a power of less than 35 kW, the diameter is at least 13 cm, and with a power of 35-45 kW - 14 cm.

The need for engineering communications

In addition to the coordinated connection to the gas main, the operation of gas boilers is impossible without a water supply and electrical network. Water supply in a significant amount, because. water is the main heat carrier in the heating system. Such an additional point also requires coordination with the relevant organizations and the installation of water flow control devices.

Almost all types of gas boilers cannot work without electricity. When summing up the electrical network, the total need for electricity is taken into account - for the boiler (according to the passport) and lighting of the room.

note

The line must be diverted from an individual switchboard equipped with an automatic switch, a protection system and a meter.

Installation of a floor boiler

Installation of a floor-standing gas boiler is carried out in the following order:

- Building a solid foundation. For powerful boilers, a monolithic one is required, and for low-power equipment, a metal sheet.

- Installing the boiler after checking the levelness of the base with .

- Connecting the boiler to the chimney and checking for the necessary draft.

- Connecting the pipes of the heating system. Installation of a filter for cleaning and water hardness, as well as locking elements in accordance with the instructions. Ball valves are usually installed.

- Summing up and connecting the water supply in the presence of a second circuit.

When installing equipment, it should be remembered that tapping into the gas main can only be carried out by a specialist with a special permit.

Conditions for placing a wall-mounted boiler

Another common type of equipment is wall-mounted gas boilers. Their installation is provided in the following sequence:

- The equipment is fixed on a load-bearing, high-strength wall or partition that meets the requirements of fire resistance.

- The boiler body must be 45-55 mm from the wall surface and 50-60 cm from the adjacent wall. There must be a distance of at least 75 cm from the ceiling. The boiler is mounted strictly parallel to the floor surface.

- Installation of a water filter and locking elements. Connection to the heating system.

- Installation of a chimney, if provided for by the instructions.

- Connection to the gas pipeline.

- Summing up the electrical network.

When installing both types of boilers, it must be taken into account that it can only be carried out at a room temperature within 6-34 degrees. After installation, the unit is slowly filled with water so that all the air is forced out.

Equipment maintenance

The operation of gas equipment must be carried out strictly in accordance with the instructions. It should always be remembered that any violations and gas leaks can lead to tragic consequences. Do not use worn or damaged equipment.

Boiler maintenance must be provided at least 2 times a year. Before the onset of cold weather, it is carried out without fail and in full. The tightness of all connections, the condition of the chimney and the ventilation system are checked. The filters and burner are thoroughly cleaned. If necessary, worn parts and seals are replaced.

Gas boilers are increasingly used for heating and hot water supply of private houses. They are easy to operate, and safety is guaranteed when properly installed and operated.

Installation of equipment must be ensured in full compliance with established standards. It is important to remember that the uncoordinated connection of such boilers is a serious offense and is fraught with administrative punishment.

A gas boiler is the best way to create a reliable and heating network for your home. Such equipment is characterized by high efficiency at low financial costs for use, and also makes it possible to flexibly regulate the heating of internal premises. We will talk about the requirements for the room where it is planned to install the boiler, the characteristics of the heating equipment and the rules for its installation in this article.

Preparations for the installation of the boiler - regulations and project documentation

For the competent installation of a gas boiler in a cottage, in a country house or in a private house, you must first familiarize yourself with the existing regulatory documentation governing the rules for performing such work. The standards describe the features of the installation of gas equipment to create an autonomous heating system.

First of all, you should study SNiP 31-02-2001 on gas supply to country houses. Here are all the legal requirements for the installed gas equipment. In addition, information on the requirements for the installation of an autonomous heating system is also contained in the documents:

- SNiP 41-01-2003 on ventilation, heating and air conditioning;

- SNiP 2.04.01-85 on the arrangement of internal water supply;

- SNiP 21-01-97 on fire safety;

- SNiP 2.04.08-87 rev.

According to these requirements, in order to install a boiler in a house, it is necessary to first obtain the technical conditions that are the basis for organizing work on connecting home equipment to the central gas supply line. To obtain technical specifications, you need to contact the local gas service and submit an application, indicating in it the estimated gas consumption for heating needs. In central Russia, gas heating consumes from 7 to 12 m 3 of gas per day.

The submitted application will be considered by the company's specialists, if it is possible to organize the connection, the owner will receive technical conditions, but if for some reason it is impossible to provide gas to the house, the owner of the facility will be given a reasoned refusal. The procedure for considering the application takes place within one month, but the owner can receive a response much earlier.

The technical conditions are the official permission for the installation of gas equipment. Performing work without specifications is considered illegal and dangerous for users of the home.

Having received the technical conditions, you can proceed to the creation of a project for connecting the facility to gas supply. The project should contain a diagram of the installation of gas communications - gas supply pipes from the central highway to a private land plot and from the place where the plot is connected inside the house.

Gas supply design is allowed to be carried out only by qualified specialists who have all the relevant permits and licenses to perform such work. It is impossible to independently prepare a project for connecting to the network. The finished project is submitted for approval to the department of the organization that controls the gas supply in the settlement. Coordination is carried out within 90 days from the date of submission of the application by the owner.

When submitting an application for project approval, the following documents must be attached to it:

- registration certificate and instructions for using the installed boiler;

- certificates of conformity;

- confirmation of compliance of the gas unit with safety requirements.

If for some reason the gas service decides to refuse to approve the project to the owner, he will be given a reasoned refusal and a list of actions necessary to obtain permission to connect the house to gas supply and install gas equipment.

Requirements for the premises - where can I arrange a boiler room?

Gas equipment differs in power. Devices with a power of less than 30 kW can be installed in any non-residential premises, and for more powerful devices, a boiler room is required. A boiler room is a separate room designed exclusively for the placement of heating equipment and not used for other needs.

Most often, for the installation of a boiler room in a house, premises in the basement are used; the room must comply with all modern requirements and standards. The installation of a boiler room in the basement is allowed only in single-apartment residential buildings. You can also place the boiler in an attached room to the house.

The legislation regulates the requirements for the boiler room:

- 1. The area of the room for the installation of heating equipment should be from 4 m 2 or more. Only 2 boilers can be installed in one boiler room.

- 2. The ceiling height of the boiler room is at least 2.2 m.

- 3. A window for lighting is needed in the boiler room, its size is calculated according to the formula - for every 10 m 3 of the volume of the boiler room there should be 0.3 m 2 of the window area. The minimum window area is 50 cm 2 .

- 4. The width of the doorway - from 80 cm.

- 5. The distance to the door is at least 1 m, but it is better to place gas equipment further from the entrance, at least at a distance of 1.3 m.

- 6. In front of the boiler, free space is provided for the repair and maintenance of equipment - from 1.3 m.

The boiler in the room must be installed strictly horizontally. Such installation will minimize the noise and vibrations that occur during its operation. The equipment is installed only on a flat floor made of durable, non-combustible materials. The walls in the boiler room must also be built and lined with materials that are fireproof and heat-resistant.

For the normal and safe operation of the boiler room, it is necessary to supply cold water to it, as well as organize a system for draining water into the sewer located in the floor. All electrical outlets in the room must be grounded. In the room, access to the chimney must be organized so that when servicing the equipment it is possible to control the patency of the channels and perform cleaning.

Chimney and ventilation system

According to the rules for the installation of gas equipment in the room where the boiler is installed, it is necessary to organize functional ventilation and smoke removal systems. If these systems are not in the room, or they cannot function normally, this can cause damage to expensive equipment and emergencies.

The ventilation and chimney ducts in the boiler room must be separate. The ventilation system should work not only to remove air from the room, but also to supply pure oxygen, therefore, it is necessary to organize a functional supply and exhaust system. The entrance window of the ventilation duct is made at the bottom of the front door or in the outer wall. The size of the opening should be at least 1/30 of the boiler room area and at least 8 cm 2 per 1 kW of boiler power (if the air is supplied from the street). If air enters the room from another room, then the size of the hole is made from 30 cm 2 per 1 kW. In the boiler room, the ventilation duct must always be open so that air can constantly circulate in the room.

The boiler is best installed in the immediate vicinity of the chimney. The chimney installed in the wall must have two channels:

- main - for pipe installation;

- revision - for maintenance (located below the main one at a distance of 25 cm or more).

The outlet of the chimney must necessarily correspond in size to the outlet pipe of the installed gas equipment. The chimney itself should have no more than 3 turns and bends. The system pipe is made of stainless steel or carbon steel sheet. Installation of pipes made of asbestos or other layered materials may only be carried out at a distance of 50 cm from the boiler chimney.

Before installing the chimney, it is necessary to calculate its optimal location and length. Such a calculation will increase the functionality of the system and make it safe to operate. For pipes used in chimneys, the following requirements apply:

- the pipe must rise above the roof without a ridge by at least 50 cm;

- a pipe that opens onto a slope at a distance of less than 150 cm from the ridge is equipped with a head that rises half a meter above the ridge;

- a pipe exiting through a pitched roof at a distance of more than 150 cm from the ridge, but less than 300 cm, must have a head not lower than the top of the ridge;

When the distance from the pipe on the pitched roof to the ridge is more than 300 cm, the head is positioned so that its height reaches a conditional line drawn at an angle of 10˚ from the top of the ridge to the horizon.

Types and features of connecting gas equipment

In the gas equipment market, boilers are presented in a wide range, the owners of private houses can only choose the right devices that meet their characteristics of the installation site and the requirements for heating intensity. There are several options for classifying boilers, such devices are divided according to the following criteria:

- according to the method of installation;

- by design;

- by power;

- according to the method of ignition;

- according to the method of removal of combustion products.

According to the design characteristics, boilers are divided into single- and double-circuit ones. Devices with one circuit are designed exclusively for heating. If necessary, organize hot water supply in the house, you will have to use an additional device - a boiler. Double-circuit models can ensure the operation of hot water and heating systems at the same time. They work on the flow heating principle or have a built-in boiler that heats the water to the required temperature. Due to this, dual-circuit devices are considered more versatile, but also more expensive.

According to the installation method, the devices are divided into wall and floor. Floor-standing devices differ from wall-mounted ones in their large size and power, which is why they sometimes require installation in a special boiler room. Wall-mounted boilers have become more popular lately, because their use is possible both in private houses and in apartments. Wall-mounted appliances are good because they do not require the installation of a full-fledged chimney, the removal of combustion products can be carried out through an external wall through a coaxial chimney.

A very important parameter when choosing a boiler is its power. To guarantee high-quality heating of all internal premises of a residential facility, it is necessary to first calculate the power of gas equipment. For efficient heating of every 10 m 2 of the area of the house, at least 1 kW of boiler power is required. It is highly desirable to choose a device with a power reserve of 20%, so that during operation it does not have to work at its limit.

It should be borne in mind that the specific power for heating 10 m 2 of the area of \u200b\u200bthe house varies for different regions of Russia. If in the middle lane 1 kW is enough, then for the north it is better to carry out the calculation, taking as a specific power a value of 1.5 or even 2 kW. In the southern regions, such power is not needed, it is quite enough to carry out calculations with specific power indicators at the level of 0.7-0.8 kW.

Rules for installing a heating system

It is best to entrust the task of installing gas equipment to qualified specialists who will be able to perform the necessary work correctly, in full compliance with modern legislation, and will make a safe and functional system for your home. Sometimes you can perform installation work on your own, but for this you will have to obtain personal permission from representatives of regulatory organizations, but even in this case, the acceptance and testing of the installed boiler must be carried out by professionals.

Before starting installation, you need to make sure that you have purchased all the necessary equipment and components; for this, you should re-examine the prepared installation project and the technical documentation for the boiler being installed. After that, the floor unit is installed on a solid surface, the ideal mounting base is a concrete screed covered with a metal sheet or ceramic tiles. Such a floor is needed not only under the boiler itself, but also in the entire pre-furnace space - about 40-50 cm in front of the boiler.

The device is installed on the base in such a way that it rests firmly on the surface with all legs. An unstable installation may cause the device to malfunction.

During installation, the following requirements must be met:

- distance from the surface of the boiler to the ceiling - from 1.2 m;

- distance from the boiler to an unprotected wall - from 32 cm;

- distance to a wall closed with a metal sheet - from 26 cm;

- distance from the chimney to an unprotected wall - from 50 cm;

- distance from the chimney to the protected wall - 25 cm;

For mounting wall-mounted boilers, special brackets or mounting strips included in the device kit are mounted in the wall. Installation must be carried out at a height of 1 to 1.6 m from the floor. It is necessary to install brackets and strips at the building level so that the boiler is suspended exactly vertically and horizontally. The device is hung on the installed mounts.

Next, the boiler is connected to the installed chimney through a special branch pipe (the fastening of the branch pipe to the pipe must be tight without gaps). After that, water is poured into the heating pipeline through the water supply system (a coarse filter and stopcocks are mounted on the pipe before entering the boiler on both sides of it). It is very difficult to ensure the tightness and proper operation of the system on your own, therefore we once again recommend contacting professionals to install the device.

INDOOR GAS SUPPLY DEVICES

GENERAL INSTRUCTIONS

6.1. The provisions of this section apply to design of gas pipelines and gas equipment placed inside buildings and structures for various purposes.

Possibility of installation of gas equipment and laying of gas pipelines in specific buildings should be determined in accordance with building codes and rules for the design of the relevant buildings.

LAYING OF GAS PIPELINES

6.2. Gas pipelines laid inside buildings and structures should be provided from steel pipes that meet the requirements of Sec. eleven.

For connecting mobile units, portable gas burners, gas appliances, instrumentation and automation devices, it is allowed to provide rubber and rubber-fabric sleeves. When choosing hoses, one should take into account their resistance to the transported gas at a given pressure and temperature.

6.3. The connection of pipes should be provided, as a rule, by welding. Detachable (threaded and flanged) connections may be provided only at the installation sites of shut-off valves, gas appliances, instrumentation, pressure regulators and other equipment.

The installation of detachable connections of gas pipelines should be provided in places accessible for inspection and repair.

6.4. The laying of gas pipelines inside buildings and structures should be provided, as a rule, open. It is allowed to provide for hidden laying of gas pipelines (except for LPG gas pipelines and gas pipelines inside residential buildings and public buildings of a non-industrial nature) in the furrows of walls closed with easily removable shields with openings for ventilation.

6.5. In industrial premises of industrial enterprises, including boiler houses, buildings of consumer services enterprises for industrial purposes and public catering, as well as laboratories, it is allowed to lay gas pipelines to individual units and gas appliances in the floors of a monolithic structure, followed by sealing the pipes with cement mortar. In this case, it is necessary to provide for painting pipes with oil or nitro-enamel waterproof paints.

At the points of entry and exit of the gas pipeline from the floor, cases should be provided, the ends of which should protrude above the floor by at least 3 cm.

6.6. In industrial premises of industrial enterprises, it is allowed to lay gas pipelines in the floor in channels covered with sand and covered with slabs.

Channel designs must exclude the possibility of gas spreading under the floor.

The laying of gas pipelines in channels is not allowed in places where, according to production conditions, substances that cause corrosion of pipes can get into the channels.

6.7. Channels intended for laying gas pipelines, as a rule, should not intersect with other channels.

If it is necessary to cross the channels, it is necessary to provide for the installation of sealing jumpers and the laying of gas pipelines in cases made of steel pipes. The ends of the cases must extend beyond the lintels by 30 cm in both directions.

6.8. Gas pipelines, when laid jointly with other pipelines on common supports, should be placed above them at a distance that ensures ease of inspection and repair.

6.9. The laying of gas pipelines in transit through industrial premises where gas is not used may be provided for low and medium pressure gas pipelines, provided that fittings are not installed on the gas pipeline and unhindered round-the-clock access to these premises is provided for the personnel servicing the gas pipeline.

6.10. It is not allowed to provide for the laying of gas pipelines in rooms belonging to categories A and B in terms of explosion and fire hazard; in explosive zones of all premises; in basements; in storage buildings of explosive and combustible materials; in the premises of substations and switchgears; through ventilation chambers, shafts and channels; elevator shafts; garbage collection rooms; chimneys; through rooms where the gas pipeline may be subject to corrosion, as well as in places where aggressive substances can be exposed and in places where gas pipelines can be washed by hot combustion products or come into contact with heated or molten metal.

6.11. For internal gas pipelines experiencing temperature effects, it should be possible to compensate for temperature deformations.

6.12. For gas pipelines transporting wet gas and laid in rooms where the air temperature can be below 3 ° C, thermal insulation from non-combustible materials should be provided.

6.13. Disconnecting devices on gas pipelines in industrial premises of industrial and agricultural enterprises, consumer service enterprises of an industrial nature should be provided for:

at the input of the gas pipeline indoors;

on branches to each unit;

in front of burners and igniters;

on purge pipelines, in places where they are connected to gas pipelines.

If there is a gas meter or GRU inside the premises, located at a distance of no more than 10 m from the gas pipeline entry point, a valve or valve in front of the GRU or meter is considered to be a disconnecting device at the input.

Installation of fittings on gas pipelines laid in channels, in a concrete floor or in wall furrows is not allowed.

6.14.* The need to account for gas consumption and the choice of a metering system at gas supply facilities should be determined in accordance with the instructions of the "Rules for the use of gas in the national economy", approved by the Ministry of Gas Industry, and the "General Regulations on the procedure for recording and controlling the consumption of fuel, electric and thermal energy for industrial , transport, agricultural and household enterprises and organizations”, approved by the State Committee on Science and Technology, the State Planning Committee of the USSR, Gosstandart.

By decision of the executive authorities of the constituent entities of the Russian Federation on the procedure for accounting for gas consumption by consumers and regulating gas prices in gasified residential buildings, as well as in the gasification of greenhouses, baths and other household buildings, it should be possible to account for gas consumption by each subscriber by installing on a gas pipeline (in apartment, individual house) gas metering device - meter.

6.15. Devices for measuring gas consumption should be placed in hydraulic distribution stations or gasified premises. It is allowed to place devices for measuring gas consumption in other rooms not lower than II degree of fire resistance, with exhaust ventilation.

It is allowed to install no more than two gas meters in parallel on one gas pipeline.

6.16. The laying of gas pipelines in residential buildings should be provided for non-residential premises.

In existing and reconstructed residential buildings, it is allowed to provide for the transit laying of low-pressure gas pipelines through living rooms in the absence of the possibility of another laying. Transit gas pipelines within residential premises should not have threaded connections and fittings.

It is not allowed to provide for the laying of gas pipeline risers in living rooms and sanitary facilities.

6.17.* The installation of disconnecting devices on gas pipelines laid in residential buildings and public buildings (with the exception of catering establishments and consumer service enterprises of an industrial nature) should be provided for:

to turn off risers serving more than five floors;

in front of the counters (if a disconnecting device at the input cannot be used to turn off the counter);

in front of each gas appliance, oven or installation;

on branches to heating furnaces or appliances in accordance with the requirements of clause 6.46.

On the supply gas pipelines to cooking boilers, restaurant stoves, heating stoves and other similar equipment, two shut-off devices should be installed in series: one to turn off the device (equipment) as a whole, the other to turn off the burners.

On the supply gas pipelines to gas appliances, in which a shut-off device in front of the burners is provided in their design (gas stoves, water heaters, stove burners, etc.), it is necessary to install one shut-off device.

The need to install devices for disconnecting risers (entrances) of 5-storey and less residential buildings is decided by the design organization, depending on local specific conditions, including the number of storeys of buildings and the number of apartments to be disconnected in case of emergency and other works.

Devices provided for disconnecting risers (entrances) should be installed, if possible, outside the building.

6.18. The distance from gas pipelines laid openly and in the floor inside the premises to building structures, technological equipment and pipelines for other purposes should be taken from the condition of ensuring the possibility of installation, inspection and repair of gas pipelines and fittings installed on them, while gas pipelines should not cross ventilation grilles, window and doorways. In industrial premises, it is allowed to cross light openings filled with glass blocks, as well as to lay a gas pipeline along the bindings of non-opening windows.

6.19. The minimum clear distances between the gas pipeline laid along the wall of the building and communication and wire broadcasting facilities should be taken in accordance with the "Safety Rules for Working on Cable Communication Lines and Wire Broadcasting" approved by the USSR Ministry of Communications in the prescribed manner.

6.20. The distances between gas pipelines and engineering communications of power supply located inside the premises, at the places of convergence and intersection should be taken in accordance with the PUE.

6.21. The laying of gas pipelines in places where people pass should be provided at a height of at least 2.2 m from the floor to the bottom of the gas pipeline, and in the presence of thermal insulation - to the bottom of the insulation.

6.22.* Fastening of openly laid gas pipelines to walls, columns and ceilings inside buildings, frames of boilers and other production units should be provided using brackets, clamps, hooks or hangers, etc. at a distance that provides the possibility of inspection and repair of the gas pipeline and fittings installed on it.

The distance between the supporting fasteners of gas pipelines should be determined in accordance with the requirements of SNiP 2.04.12-86.

6.23. The laying of gas pipelines transporting wet gas (except for the vapor phase of low-pressure LPG) should be provided with a slope of at least 3 o / oo.

If there is a gas meter, the slope of the gas pipeline should be provided from the meter.

6.24. Vertical gas pipelines at the intersections of building structures should be laid in cases. The space between the gas pipeline and the case must be sealed with tarred tow, rubber bushings or other elastic material. The end of the case should protrude above the floor by at least 3 cm, and its diameter should be taken from the condition that the annular gap between the gas pipeline and the case is at least 5 mm for gas pipelines with a nominal diameter of not more than 32 mm and not less than 10 mm for gas pipelines of a larger diameter.

6.25. Internal gas pipelines, including those laid in channels, should be painted. For painting, waterproof paints and varnishes should be provided.

6.26. Gas appliances and gas burners should be connected to gas pipelines, as a rule, with a rigid connection.

Connection to the gas pipeline of gas appliances, laboratory burners, as well as portable and mobile gas burners and units installed in the workshops of industrial enterprises is allowed to be provided after the shut-off valve with rubber-fabric sleeves. Rubber-fabric sleeves for connecting household gas appliances and laboratory burners should not have butt joints.

6.27. On gas pipelines of industrial (including boiler houses), agricultural enterprises, consumer service enterprises of an industrial nature, purge pipelines should be provided from the sections of the gas pipeline that are most remote from the entry point, as well as from branches to each unit before the last shut-off device along the gas flow.

It is allowed to combine purge pipelines from gas pipelines with the same gas pressure, with the exception of purge pipelines for gases with a density greater than that of air.

The diameter of the purge pipeline should be taken at least 20 mm.

After the shut-off device on the purge pipeline, a fitting with a sampling cock should be provided, if a fitting for connecting an igniter cannot be used for this.

In some cases (for example, for cutting and welding posts, small industrial furnaces), with a supply gas pipeline with a diameter of not more than 32 mm, it is allowed to install a shut-off device with a blind plug-plug instead of purge pipelines.

6.28. The distance from the end sections of the purge pipelines to the supply ventilation intake devices must be at least 3 m.

When the building is located outside the lightning protection zone, the outlets of the purge pipelines should be grounded.

GAS SUPPLY OF RESIDENTIAL BUILDINGS

6.29. The installation of gas stoves in residential buildings should be provided for in kitchens with a height of at least 2.2 m, having a window with a window (panel), an exhaust ventilation duct and natural lighting.

At the same time, the internal volume of the kitchen premises should be, m3, not less than:

for gas stove with 2 burners 8

« « « « 3 « 12

« « « « 4 « 15

6.30. In existing residential buildings, it is allowed to install gas stoves:

in kitchen rooms with a height of at least 2.2 m and a volume of at least that specified in clause 6.29 in the absence of a ventilation duct and the impossibility of using chimneys as such a channel, but if there is a window in the room with a window or transom in the upper part of the window;

in the corridors of individual use, if there is a window in the corridor with a window or a transom in the upper part of the window, while the passage between the slab and the opposite wall must be at least 1 m wide, the walls and ceilings of the corridors made of combustible materials must be plastered, and the living quarters must be separated from corridor with dense partitions and a door;

in kitchens with sloping ceilings, having a height in the middle part of at least 2 m, the installation of gas equipment should be provided in that part of the kitchen where the height is at least 2.2 m.

6.31. * In existing residential buildings owned by citizens on the basis of personal property rights, it is allowed to install gas stoves in rooms that meet the requirements of paragraphs. 6.29 or 6.30, but having a height of less than 2.2 m to 2 m inclusive, if these rooms have a volume of at least 1.25 times the normative one. At the same time, in houses that do not have a separate kitchen, the volume of the room where the gas stove is installed must be twice as large as specified in clause 6.29.

If it is impossible to fulfill the specified requirements, the installation of gas stoves in such premises may be allowed in each specific case upon agreement by the local sanitary supervision authority.

6.32.* The possibility of installing gas stoves, heating and other appliances in buildings located outside a residential building is decided by the design organization and the operating organization of the gas economy, taking into account specific local conditions, including the availability of gas for these purposes. At the same time, the premises in which the installation of gas appliances is provided must comply with the requirements for the premises of residential buildings where such appliances are allowed.

6.33. Wooden non-plastered walls and walls made of other combustible materials in the places where the plates are installed should be insulated with non-combustible materials: plaster, roofing steel on an asbestos sheet with a thickness of at least 3 mm, etc. The insulation should protrude beyond the dimensions of the plate by 10 cm on each side and at least 80 cm above.

The distance from the stove to the walls of the room insulated with non-combustible materials must be at least 7 cm; the distance between the slab and the opposite wall must be at least 1 m.

6.34. For hot water supply, instantaneous or capacitive gas water heaters should be provided, and for heating - capacitive gas water heaters, small-sized heating boilers or other heating devices designed to run on gas fuel.

The number of storeys of residential buildings in which the installation of these gas appliances and apparatus is allowed should be taken in accordance with SNiP 2.08.01-89.

6.35. Small-sized (small-sized) factory-made heating boilers designed for solid or liquid fuels are allowed to be converted to gas fuel.

Heating installations converted to gas fuel must be equipped with gas burners with safety automatics in accordance with the requirements provided for in Sec. eleven.

It is not allowed to provide for the installation of more than two storage water heaters or two small-sized heating boilers or two other heating devices in one room.

6.36. The arrangement of chimneys must comply with the requirements of SNiP 2.04.05-91 * as for heating stoves. When deciding on the possibility of connecting gas appliances to chimneys, it is allowed to be guided by the data given in reference Appendix 6.

6.37.* Installation of water heaters, heating boilers and heating devices should be provided in kitchens and non-residential premises intended for their placement and meeting the requirements of paragraphs. 6.42* and 6.43. Installation of these appliances in bathrooms is not allowed. The question of the need to relocate gas water heaters from the bathrooms, in which they were placed in accordance with the previously applicable standards, to the kitchens or other non-residential premises of a residential building during the reconstruction of a house or a gas supply system should be decided in each case by the design organization in agreement with local operating organizations gas economy.

In existing residential buildings, it is allowed to provide for the installation of gas heating appliances and heating appliances in corridors for individual use that meet the requirements of paragraphs. 6.42* and 6.43.

The distance from the protruding parts of gas burners or fittings to the opposite wall must be at least 1 m.

6.38. Installation of gas instantaneous water heaters should be provided on walls made of non-combustible materials at a distance of at least 2 cm from the wall (including from the side wall).

In the absence of walls made of non-combustible materials in the room, it is allowed to provide for the installation of an instantaneous water heater on plastered, as well as on walls lined with non-combustible or slow-burning materials at a distance of at least 3 cm from the wall.

The surface of slow-burning walls should be insulated with roofing steel on an asbestos sheet with a thickness of at least 3 mm. The insulation should extend beyond the dimensions of the water heater body by 10 cm.

6.39. The installation of gas heating boilers, heating appliances and capacitive gas water heaters should be provided near walls made of non-combustible materials at a distance of at least 10 cm from the wall.

If there are no walls made of non-combustible materials in the room, it is allowed to install the above heating devices near the walls protected in accordance with the instructions of clause 6.38, at a distance of at least 10 cm from the wall.

6.40. The horizontal distance in the light between the protruding parts of the instantaneous water heater and the gas stove should be taken at least 10 cm.

6.41.* When installing a gas stove and instantaneous water heater in the kitchen, the volume of the kitchen should be taken in accordance with clause 6.29.

When installing a gas stove and a storage water heater, a gas stove and a heating boiler or a heating apparatus, as well as a gas stove with built-in devices for heating water (heating, hot water supply) in the kitchen, the volume of the kitchen must be 6 m3 more than the volume provided for in clause 6.29.

6.42.* The room intended for the placement of a gas water heater, as well as a heating boiler or a heating apparatus, the removal of combustion products from which is provided for in the chimney, must have a height of at least 2 m. The volume of the room must be at least 7.5 m3 when installing one device and not less than 13.5 m3 when installing two heaters.

6.43. The kitchen or room where boilers, appliances and gas water heaters are installed must have a ventilation duct. For air inflow, in the lower part of the door or wall facing the adjacent room, a grate or a gap between the door and the floor with a free area of at least 0.02 m2 should be provided.

6.44.* It is not allowed to place all gas appliances in the basement floors (cellars), and in the case of LPG gas supply - in the basement and basement floors of buildings for any purpose.

Note. The requirements of this paragraph do not apply to residential buildings owned by citizens on the basis of personal property rights, if the basements of these houses have natural lighting, and their gas supply is carried out from natural gas.

6.45. It is allowed to transfer heating and heating-cooking stoves to gas fuel, provided that:

stoves, smoke and ventilation ducts meet the requirements of departmental standards for the installation of heating stoves converted to gas fuel, approved in the prescribed manner;

gas burners installed in the furnaces of heating and heating-cooking furnaces are equipped with safety automatics in accordance with the requirements of GOST 16569-86.

6.46. The furnaces of gasified furnaces should be provided, as a rule, from the side of the corridor or other non-residential (non-service) premises.

If it is impossible to ensure the specified requirement, it is allowed to provide fireboxes for gasified furnaces from the side of residential (office) premises. In this case, the gas supply to the furnaces should be provided by independent branches, on which, at the point of connection to the gas pipeline, a disconnecting device should be installed outside the above premises.

The premises into which the fireboxes of gasified heating and heating-cooking stoves exit must have an exhaust ventilation duct or a window with a window, or a door leading to a non-residential premises or vestibule. There must be a passageway at least 1 m wide in front of the oven.

6.47. For space heating, it is allowed to provide gas fireplaces, heaters and other factory-made appliances with the removal of combustion products into the chimney. The gas-burning devices of these devices must be equipped with safety automatics in accordance with the requirements provided for in Sec. eleven.

The room in which it is planned to install a gas fireplace or heater must have a window with a window or an exhaust ventilation duct.