Drilling rig for water drilling. Small drilling rigs. Small-sized rotary drilling rigs

Extraction of water is one of the most ancient crafts of mankind. Modern technologies allow today to drill wells with a depth of more than a kilometer.

The more complex the soil structure, and the further the aquifer, the more powerful a drilling rig for water wells will be needed to get to the desired mark. Our instruction, as well as the video in this article, will help you understand the methods of drilling and the types of installations used.

Types of wells and their development

Many are interested in whether it is possible or a well with their own hands. Theoretically, it is possible, but in practice, so many difficulties often arise!

Let's take a well. If groundwater is located no deeper than six meters, problems may not arise.

So:

- Although, even at this depth, there may be a mass content of solid inclusions in the soil, which will greatly complicate excavation. But, in this case, you can at least dig a pit with an excavator.

And if the depth of the mine is 10-15m or more? Digging, in this case, has to be done manually, and this can become truly hard labor. - In addition to being very time consuming, this process is also time consuming. In addition, there is no guarantee that you will not end up on a sandy quicksand.

The content of sand in the water from quicksand exceeds the permissible limits. At the same time, any filter will quickly become clogged, making it difficult for water to flow into the well.

Conventional wells

A normally functioning water intake should not be arranged on a quicksand, but on a sandy aquifer. Most often, they are located at around 20-45 meters.

For a well, this is an impressive mark, and for a well, it is the minimum possible depth.

So:

- Sandy layers give a smaller volume of water than calcareous, which lie much deeper. Therefore, the service life cannot be predicted.

We can only say approximately - this is 7-10 years. As soon as the limit is exhausted, it needs to be deepened, or liquidated, and a new one drilled.

- Today, two methods of drilling are used: rotary and auger (see). The essence of the first is the destruction of constantly moistened rocks with a drill.

It rotates due to the force of the rotor - hence the name of the method. The rotor can be installed both on a mobile drilling rig and on a stationary one with its own engine. - The walls of the wellbore are reinforced with casing pipes, after which drilling continues with a cone bit. The deeper the drill goes, the smaller the size of the bit used. Typically, the rotary method is used for drilling to a depth of 50-55 meters.

- At an average depth (from 55 to 80 m) they drill dry, using a screw method. For this, a welded pipe structure is used. You can see it in the photo at the beginning of the article.

The auger has a spiral shape, and cutters are rigidly fixed at the end. They destroy the rock, which is fed "to the mountain" by a conveyor. When hitting especially hard rocks, special drills with several cutters are used.

tubular wells

There is such a thing as . It is of small depth (up to 30 m), and with a very small diameter.

Otherwise, it is called a tubular well. It usually does not exceed two inches - and this is only 5.08 cm.

So:

- To get a well of this diameter, a steel extension rod is manually driven into the ground.

Drilling wells for water with mini installations greatly simplifies this task. And the price is quite enough to buy it for personal use.

- As casing pipes, in this case, ordinary gas pipes are used. They are connected by carving into a long column, which is called a "needle".

This association is caused by the first pipe with a cone-shaped tip. Its diameter exceeds the corresponding size of the pipes in order to eliminate friction and facilitate their passage through the soil. - In fact, the Abyssinian well is drilled using both of the above methods. First, the work goes dry, with the largest possible drill (2 inches).

As soon as the well reaches the level of quicksand containing water, the drill is changed to a “needle” with a tip, and alternate driving of all segments of the string begins. - A perforated pipe wrapped with a special mesh is mounted to the segment with a tip - this is a filter. All segments are interconnected by couplings, and sealed with silicone.

In principle, this technological process has much in common with conventional wells. The difference arises in connection with their dimensions: depth and diameter.

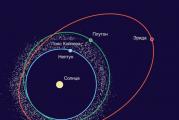

Artesian

The deepest are artesian. It is they who draw water in limestone layers.

Despite the impressive depth, water supply from an artesian well can be carried out by a conventional submersible pump, of the same power as in a well. It is mounted at the level of the nearest aquifer sandy horizon.

So:

- The static water level in is set at the mark of the nearest body of water. The equilibrium of the water column is achieved due to the influence of interlayer pressure on the one hand, and atmospheric pressure on the other.

The presence of water in calcareous horizons is guaranteed by nature itself, and its level does not depend in any way on the terrain or, for example, climatic conditions.

- Drilling of wells with a depth of up to three hundred meters is carried out by the shock-rope method. Its essence lies in the fact that a percussion projectile, consisting of a chisel, a rod, and a lock, is lowered into the well on a rope.

Falling from a certain height, the drilling projectile crushes the rock. - The efficiency of work in the face depends on the weight and speed of the fall of the bit, its quality and the number of strokes.

The drilling tool changes, depending on the structure of the encountered soil layers. For example, formations with hard rocky rocks are passed with the help of drill chucks.

There is another method for the development of ultra-deep wells (from 600m). To do this, there are drilling rigs for drilling water wells in a shock-rotary way.

In this case, telescopic percussion rods and a solution of bentonite clay are used, with which the walls of the well are strengthened. Usually these are mobile units based on a powerful truck or tractor.

Similar equipment is used with the same success for the development of oil wells.

Creating your own source of clean water is one of the main stages in arranging a private site. Usually, water supply problems are solved by creating a well. The most significant cost item of such an event is the payment for the services of specialists involved in drilling.

However, with a strong desire, you can significantly save on such an event by assembling a home-made drilling rig and doing earthwork on your own. The manufacture of such a unit will require tangible labor and time costs, but everything will more than pay off.

There are several varieties of homemade drilling rigs. Familiarize yourself with the key features of each available option, choose the type of installation that best suits your application, and start building.

The aggregates under consideration are classified according to the features of the methods.

Thus, when percussive drilling is performed, the soil is destroyed by a heavy load tied to a support frame, the ribs of which in most cases are connected into a pyramid. The load is simply lifted up and thrown down as many times as necessary to create the desired size of the recess.

Rotating drills are both simpler and more difficult to handle. Such equipment requires much less physical effort on the part of the performer, but the design of such drilling rigs is more complex - many of the components of the system simply cannot be made by hand without special equipment and appropriate skills.

As a result, some of the necessary elements have to be bought or ordered. However, the cost of this is still significantly lower when compared with the cost of installing a factory assembly.

In general, there are 4 main types of drilling rigs, namely:

Advantages of a homemade installation

DIY Drill Rig Assembly Guide

For self-assembly of a drilling rig, it is enough to have minimal experience with, an electric drill and a grinder.

Prepare the required equipment in advance. You will need:

- tool for creating an external inch thread;

- Bulgarian;

- wrench;

- half an inch galvanized pipe, as well as a squeegee of a similar size;

- plumbing cross.

Prepare everything you need and proceed to do the job in accordance with the step-by-step guide.

First step

Prepare pipe sections for the manufacture of the main part of the drilling fixture. Pipes will need to be fixed in a spur and a cross. To do this, prepare a two-centimeter thread at the ends of the segments.

Weld pointed metal plates to the ends of several segments. They will act as tips.

Such an installation involves drilling with a constant supply of water, thanks to which the direct arrangement of the recess and the removal of the soil will be easier.

To supply water, connect a water or pump hose to any opening of the cross blank. Connect using a suitable adapter.

Second step

Proceed to connect the structural parts to the threaded connections. Connect a piece of workpiece with an equipped tip to the lower end of your working pipe. Make the connection using a squeegee.

Direct drilling will be carried out by deepening the pointed tip with the rotation of the working installation. Tip blanks should have different lengths. First you use the shortest fixture. After about a meter deep is ready, replace the short tip with a slightly longer one.

Third step

Assemble the base of the drilling structure from a square section profile. In this case, the base will be a rack with supporting components of the structure. The supports are connected to the main rack by means of a transition platform using.

Attach the platform and motor to the square profile. Fix the profile itself to the rack so that it can move along the rack. The dimensions of the profile used should slightly exceed the dimensions of the rack.

When choosing an electric motor, be sure to pay attention to its power rating. To ensure optimal drilling conditions, a 0.5 horsepower motor will suffice.

Power regulation is carried out using a gearbox. A flange must be attached to the gearbox shaft. Attach another flange to the flange with bolts. There should be a rubber washer between these two flanges. Thanks to the rubber gasket, shock loads that appear when passing through different types of soil will be smoothed out.

Fourth step

Connect water. Fluid must be continuously supplied to the main working tool by means of a drill. Without a properly organized water supply, the quality of the equipment will decrease.

The problem mentioned above can be solved by installing a special device made of steel pipe below the flanges. Prepare 2 holes in the pipe section with some shift in relation to each other.

Next, you need to make a groove on both end sides of the pipe for arranging ball bearings. You must also prepare an inch thread. At one end, the pipe is connected to the flange, and working elements will be installed at its other end.

In order to create additional moisture insulation of the created device, place it in a special polypropylene tee. Connect an adapter to the middle of this tee to connect the water supply hose.

Other models of drilling rigs

In general, the assembly process of most of the existing varieties of drilling rigs remains the same. The frame and other elements of the structure under consideration are prepared in a similar way. Only the main working tool of the mechanism can change.

Read the information on the manufacture of various types of installations, make a suitable working tool, and then attach it to the support frame and connect it to other required elements using the recommendations from the instructions discussed above.

The main working element of such a unit is a cartridge (glass). You can independently make such a cartridge from a thick-walled pipe with a diameter of 100-120 mm. The optimal length of the working tool is 100-200 cm. Otherwise, be guided by the situation. When choosing the dimensions of the support frame, you will have to take into account the dimensions of the cartridge. Think over everything so that in the future it will be convenient for you to use the finished drilling rig.

The working tool should have as much weight as possible. From the bottom of the pipe section, make triangular points. Thanks to them, the soil will loosen more intensively and quickly.

If you wish, you can leave the bottom of the workpiece even, but it will need to be sharpened.

Poke some holes in the top of the glass for attaching the rope.

Attach the chuck to the support frame using a strong cable. Choose the length of the cable so that in the future the cartridge can freely rise and fall down. When doing this, be sure to take into account the planned depth of the source.

To increase the efficiency of earthworks, you can connect the assembled unit to an electric motor. The cable with the cartridge in such a situation will be wound on the gearbox drum.

It is possible to ensure the cleaning of the bottom from the soil by including a bailer in the structure.

Using such an installation is very simple: you first manually create a recess in the drilling site with a diameter greater than the diameter of the working cartridge, and then begin to alternately raise and lower the cartridge into the hole until the required depth is reached.

Simple screw installation

Homemade auger

The main working element of such a mechanism is the drill.

Make a drill from a metal pipe with a diameter of 100 mm. Make a screw thread on the top of the workpiece, and equip an auger drill on the opposite side of the pipe. The optimal drill diameter for a homemade unit is about 200 mm. A couple of turns is enough.

Attach a pair of metal knives to the ends of the workpiece by welding. You must fix them in such a way that at the time of the vertical placement of the installation, the knives are located at a certain angle to the soil.

To work with such an installation was most convenient, connect a piece of metal pipe 1.5 m long to the tee. Fix it by welding.

Inside the tee must be equipped with a screw thread. Screw the tee itself onto a piece of a collapsible one and a half meter rod.

It is most convenient to use such an installation together - each worker will be able to take on a one and a half meter pipe.

Drilling is performed in the following order:

Repeat the cycle until you reach about a meter deepening. After the bar will have to be lengthened with an additional piece of metal pipe. A coupling is used to fasten pipes.

If it is planned to arrange a well deeper than 800 cm, fix the structure on a tripod. At the top of such a tower there should be a hole large enough for the unhindered movement of the rod.

In the process of drilling, the rod will need to be periodically increased. With an increase in the length of the tool, the mass of the structure will also increase significantly, it will become very difficult to manage it manually. For convenient lifting of the mechanism, use a winch made of metal or durable wood.

Now you know in what order simple drilling rigs are assembled and how to use such units. The knowledge gained will help you significantly save on the services of third-party drillers.

Successful work!

Video - Do-it-yourself drilling rig

Country houses and cottages are not at all a reason to refuse comfortable living conditions. Therefore, the presence of autonomous water supply in the absence of a centralized one becomes the first task of the owner. But even if water is supplied to the site from the main, its quality is so poor that its own source becomes a necessity not for comfort, but for health. And to drill a well, you just need to purchase the right tool - this is a small-sized drilling rig for water.

Large equipment can easily drill an artesian well, a mine for the extraction of oil, gas and other minerals, but small MGBUs are great for drilling water wells in private households. And, by the way, the purchase of such equipment will not particularly affect the family budget, if your site is not the only one in the area, then the drilling machine can generate rental income.

The installation has many advantages:

- Mobility and compactness of equipment;

- at the same time, MGBU for drilling water wells is easy to use;

- drilling will not harm the landscape of the site, since the well is punched by small-sized equipment;

- MGBU is very convenient for working in confined spaces and allows drilling wells in the basements of garages, adjoining buildings;

- Collapsible equipment is extremely convenient in transportation and does not require the use of special equipment for installation / dismantling, transfer;

- The MGBU receives power from a standard 220-volt outlet, but if necessary, it can operate from a mobile power source;

- MGBU works quickly, without failures (there is simply nothing to break), allowing you to quickly ensure the supply of water to a country house.

Description of MGBU

With its light weight, mobility, enhanced functionality in limited spaces, affordable cost, the drilling rig has the following set of elements:

- drilling mud pump;

- swivel to ensure free rotation of the drill, the reliability of the entire structure;

- winch - lowering / lifting tool that ensures the performance of technological operations;

- the hoist system lifts and supports the weight of the drill;

- the circular design has the function of preparing, supplying the solution.

Design features distinguish between drilling methods with small-sized installations: auger, percussion, with flushing.

Impact drilling

It is the simplest and most affordable. MGBU for drilling wells is complemented by a metal pipe with a bailer. The winch raises the pipe, then lowers it, loosening the soil pulled up by the bailer. Plus - the result is a practical good mine under water. Minuses:

- low speed of work;

- obligatory casing of the mine with large-section pipes;

- when meeting with a quicksand, the mine will simply collapse.

Important! From time to time, the glass must be cleaned of soil.

Auger drilling option

It is used for drilling wells in sand and other light soils. Functionally, the shaft is drilled by means of a rotating auger, which raises loose soil to the surface. The advantage is that all processes can be carried out pointwise and without the use of power supply. Disadvantages - obligatory excavation of the auger for cleaning.

Important! At the slightest threat of a quicksand, the auger must be immediately removed from the shaft, it will simply be pulled inside.

It is very convenient to use the auger option for drilling wells in a limited space. Due to the dotted notch with the end of the drill, which can be made into a pointed and small turning space of the spiral, the shaft is not wide, which is beneficial when equipping a water supply system, for example, in the veranda of a private house.

Flush drilling

This is one of the most productive ways to drill wells for water. The mini drilling rig can reach speeds of up to 10m/h, which is much faster than any other drilling method. Well flushing can be done in both direct and reverse ways.

Direct - this is when the solution is fed directly along the rod, washes out the soil and transfers it to the surface.

Reverse - the solution is fed into the mine, pumped out together with the soil by means of a pump.

The use of small-sized installations for drilling wells for water is also justified in terms of economic indicators - the cost of wells is low, and despite the fact that such a mine serves for at least 5-8 years, the payback of the equipment is extremely fast. There are many positives:

- drilling equipment can be disassembled, removed and used for its intended purpose at any time;

- by means of MGBU, mines are drilled under the pile foundation;

- you can always drill a mine for water in any convenient place.

The only disadvantage of small-sized water well drilling rigs is the inefficiency of their use on heavy soils; the equipment has no more drawbacks.

If there is no centralized water supply in the village in which your country house is located, then sooner or later the question of organizing water supply will definitely arise. The best option is to make a well, but this will require a special installation. Next, we will look at what small-sized well drilling rigs are and how you can make them yourself.

Of course, you can not get involved with this work at all and hire specialists. However, the price for their services varies depending on the ground conditions and can be up to $200 per meter, which is far from affordable for everyone. Therefore, if you are familiar with locksmith work, then it makes sense to do the work yourself.

In addition, having a homemade drilling rig is also a great way to earn extra money, especially if your site is located in a holiday village under construction. Moreover, the device can be used not only for drilling wells, but also for the implementation of a pile foundation.

Drilling technologies

Before starting work on the manufacture of the structure, one should consider what technology can be used to drill wells with a small-sized installation.

There are two most common methods:

- Rotational;

- Rope percussion.

Now let's look at the features of each of them.

Note! Before choosing the type of structure, it is necessary to determine the approximate depth of the ground horizon. To do this, measure the depth of wells in neighboring areas.

In the photo - self-drilling auger

Related articles:

Rotational method

This principle is reminiscent of making holes in the ice, which are made by fishermen in winter - the drill is deepened into the ground by rotation, after which it is pulled out to the surface along with the soil.

Small rigs designed for rotary drilling only drill soft ground to a relatively shallow depth.

If you want to make the installation more powerful, you will have to comply with the following conditions:

- The weight of the structure in working condition must be at least 1500 kg.

- The mechanism must be implemented on hydraulics.

- The height of the telescopic mast must be at least 5 meters.

Of the minuses of this design, the following points can be distinguished:

- The complexity of manufacturing;

- Less mobility;

- Manufacturing is expensive.

As for the advantages, it can be distinguished that well drilling with portable installations of this type can be performed at an angle. In addition, it is possible to penetrate the aquifer more accurately than with percussive drilling.

Advice! If the well is supposed to be at a shallow depth, then you can do the drilling yourself without using the installation. To do this, you only need a drill with extensible rods, which can be rotated by two people.

percussive drilling

The situation with impact drilling is much simpler. This technology appeared thousands of years ago in China.

Instructions for making a well in this way are extremely simple:

- A chisel is thrown into the ground along guides from a certain height.

- Then the chisel is lifted with the help of cables that are attached to it. For lifting, you can use an engine of sufficient power.

- Then the operation is repeated, and so on until the well reaches the required depth.

The advantages of this design are as follows:

- The drilling rig is quite compact.

- The design is reliable and has a good margin of safety.

- Shock-rope drilling of wells with small-sized installations can be performed by one person, however, it is better to get the soil out of the drill together.

- You can drill to great depths. On simple soils, the well can reach 100 meters.

- The technology is extremely simple and does not require any additional costs, for example, for drilling fluid or a pump.

- In one blow, the well can deepen up to a meter, but most often it is 20-40 cm, which is also not small.

True, it cannot be said that this method is fast. It may take a week to complete a 40-meter well. Now let's take a closer look at the device of a small-sized installation.

Installation design

At the heart of the simplest drilling rig, regardless of its type, is a tripod. Its height is usually up to five meters. At the very top of the structure there is a rope winch or a rope block, with the help of which the drill or chisel is raised to the surface by an electric motor.

Ordinary pipes can be used as materials for the tripod. If the well is carried out with a small-sized installation using the auger method, then it will be necessary to perform a drill with extension rods, which are usually fixed by a threaded method.

The rod is a device designed to transmit rotation from the engine or hands to the drill. Rods can be up to 1.8 meters long. When the structure sinks to the level of the soil, without reaching the required depth, its length is increased with the help of the next rod.

Separately, it should be said about the storm itself, which can be of several types:

- - is a steel rod with a pointed end. A pair of knives are welded to it, at a distance of about 200 mm from the sharp tip, which can be made from halves of a steel disk about 100-150 mm thick. Knives are welded at a slight angle to the horizontal - about 20 degrees.

- spoon- is a steel cylinder, with a longitudinal spiral slot. The drill spoon can be rolled up from sheet steel or made from a pipe by making a slot.

Note! The drill must be made in such a way that it plunges into the ground when rotating clockwise.

If a water well with a small-sized installation will be performed by a cable-impact method, then a chisel is needed, which can be made from a steel pipe with a special cutting device at the end. In this case, the cutting edge should be made in such a way that it resembles a half turn of the screw.

Advice! The chisel should be cleaned from the ground every one and a half meters of the recess.

Conclusion

All elements of a small installation designed for drilling wells are easy to do on your own. To do this, you only need to have the skills to work with a welding machine and a grinder. Otherwise, this issue is quite solvable.

For more information on this topic, see the video in this article.